I love science and tech and have always enjoyed my time in the laboratory trying new techniques, even if the results i get from them aren’t the greatest.

But there is one major issue in tech, especially in laboratory tech… and that is that capitalism doesn’t work.

The equipment is often a result of either of being developed for other purposes and being repurposed for the lab, or it’s a result of dedicated research for often niche lab experiments. Both often result in bad long term support, or disproportionately high prices for things that part-wise shouldn’t cost a lot.

It’s not like a lab tech can walk over to the hardware store and build their own PCR device… can they?

Well… yes… they can. All these tech developments have been mostly been made in the last 40 years, PCR machines, desk centrifuges, pipettes, robotic samples/mixers/pipetters… great equipment… but personally they often look fancy, but internally are very basic. And because a lack of competition on the market because of the small size of the market combined with users often not being engineers themselves, plus a bunch of red tape regarding certification on equipment, we don’t tend to build our own equipment (anymore). Essentially scientist have been forced out of the development part of science, where once we had to build everything ourselves, now we are forced by legislators to stick with certified external companies. We went from creators to consumers…

But… why not get back to where we once were? Get a wrench, some tools… just play around till you make something that works 😛

I worked in a lab, that due to all sorts of geopolitical and anti-free-market reasons was underfunded. A dozen employees, which means a dozen desks, which all need a dozen sets of equipment to not cause bottlenecks and arguments. One such things were Aspirators…

Aspirator… a.k.a. a suction device, is just a way to extract liquid from eppendorf tubes and other places. We used to just have a rubber balloon and a glass pipette and did it that way, then moved on to pipetting manually, to automatic suction through an aspirator.

Now our lab was short of a couple of these, i think one broke down or something like that … And the cheapest available from our supplier was $1800, the runner up $3000

Let that sink in… $1800-3000, to suck up some liquid… These machines even look cheap, a bunch of plastic parts and a couple filters… that is it

This prompted me to make my own and show my boss how much of a ripoff this was.

So, i looked over the devices we had in the lab and determined that there are a couple essential parts.

- A vacuum pump with a low suction power so it doesn’t implode the container (which might contain hazardous biological material)

- Filters to prevent liquid getting into the motor and out into the open air

- A regulator for speed, both on the motor side, and the tip side

- …… that is literally all it needs…. reminder $1800

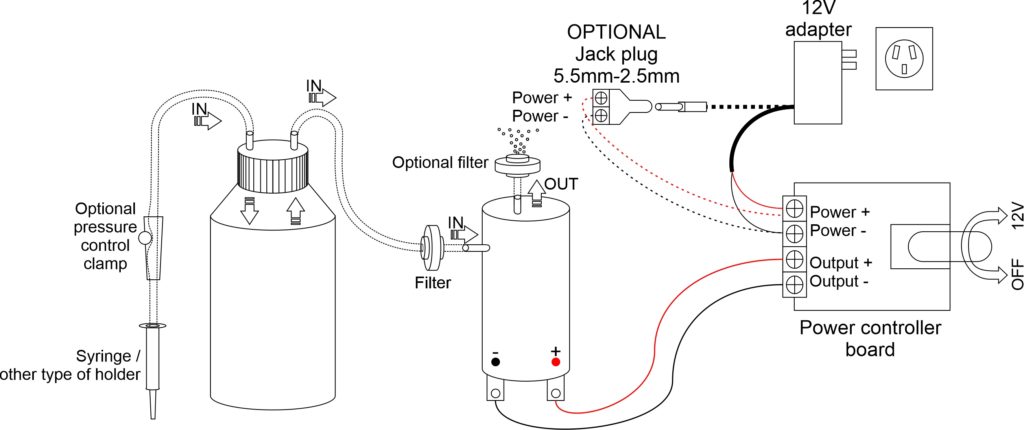

This is roughly the layout of parts needed to make it work

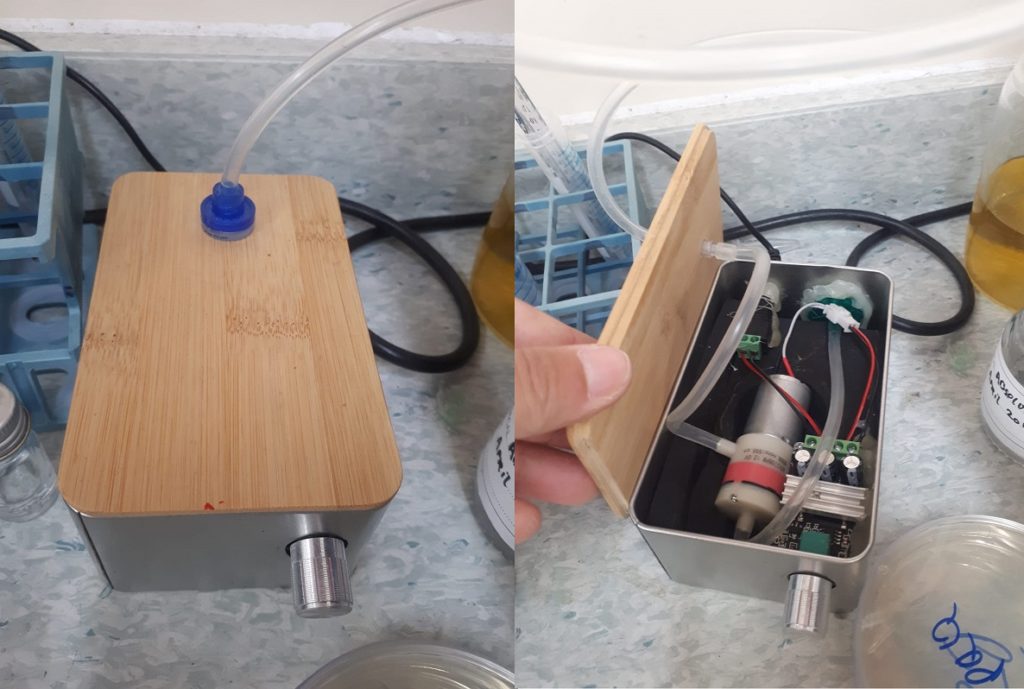

So i go on everyone’s favorite discount store that is run by my friend Alie, and look for parts. I find a 100-240 V AC power adapter that outputs 12V DC, 500mA. A small controller board that can take 12V, 3A as input, and output a range between 6V and 24V. And a vacuum pump that runs on on a max of 12 V DC, 350mA. The only problem here is that the amperage is a bit high as input (500mA, in a device that takes a max of 350mA), but i tried to solve this with just placing a resistor between the controller output and the vacuum input. And since this was a test, i just applied the basic rule of “Move fast and breaking things”.

The total costs so far? $12 USD… hmmm i guess the remaining components should cost me $1788 then.

Now we have the core, we need two filters (one between the receptacle and one where the pump pushes the air out that it sucked in… preventing liquids from entering the pump, but if they do happen, also prevent them from going out. We also need to have a nice receptacle for our liquid. And lastly a profesional looking housing for our device.

The filters are easy. Most microbial labs would have filters that prevent small particles from passing through, these can go down to viral particle size almost.

Easy-peasy, take two of these, roughly $2 bucks worth… and probably need to be replaces every once in a while…

The container we could just repurpose a 2L autoclavable medium bottle.

The only thing we need to add is a lid with two entry holes, which you can also buy, but it’s as easy as drilling two holes and then running a tube through both sides and closing it up. I used silicone kit for it, but i assume any type of semi flexible material would work as long as it’s strong enough to handle a small vacuum force. Cool… we now spend an additional $20 or $30… but these normally are already in any type of lab that needs an aspirator… so i only calculate the $2 cap that gets destroyed in the process…. we have now spend a whopping… drumrole please… ~$18….

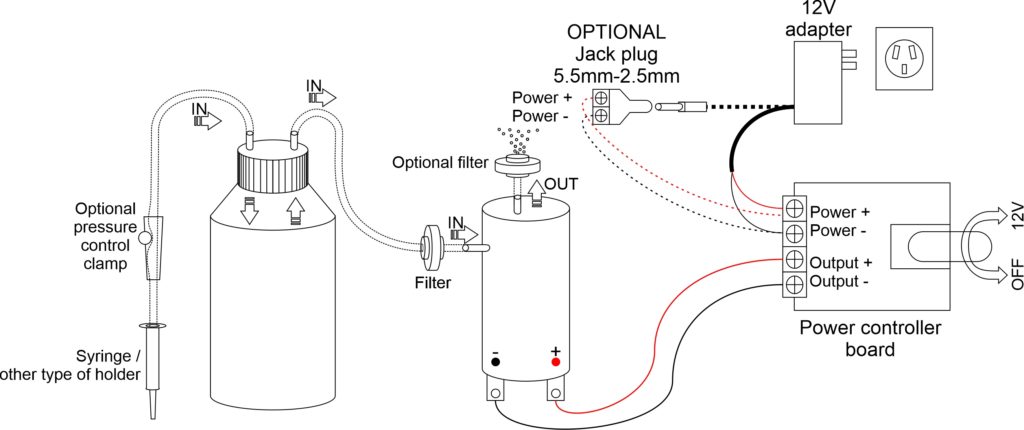

But yeah… now the most important part comes in… the housing… this is truly where engineering will shine, and we will finally see why this device is >$1800. Instead of cheap metal, i chose the finest of metals for a clean smooth and autoclavable surface…. i chose a high quality coating to make it shiny and profesional looking… i added a sleek design that shows what we are all about in science…. i …. used a coca cola can 😛

Mind you this was for the initial ‘proof of concept’

As a test i used smaller containers first before destroying this super expensive $2 bottle cap… and instead used $0.10 disposable 10ML tubes. The hoses were just normal silicone based hoses, and at the end there was a 1ML syringe (because the hose fit perfectly into it and made it airtight) and now i could put any type of tip on it….

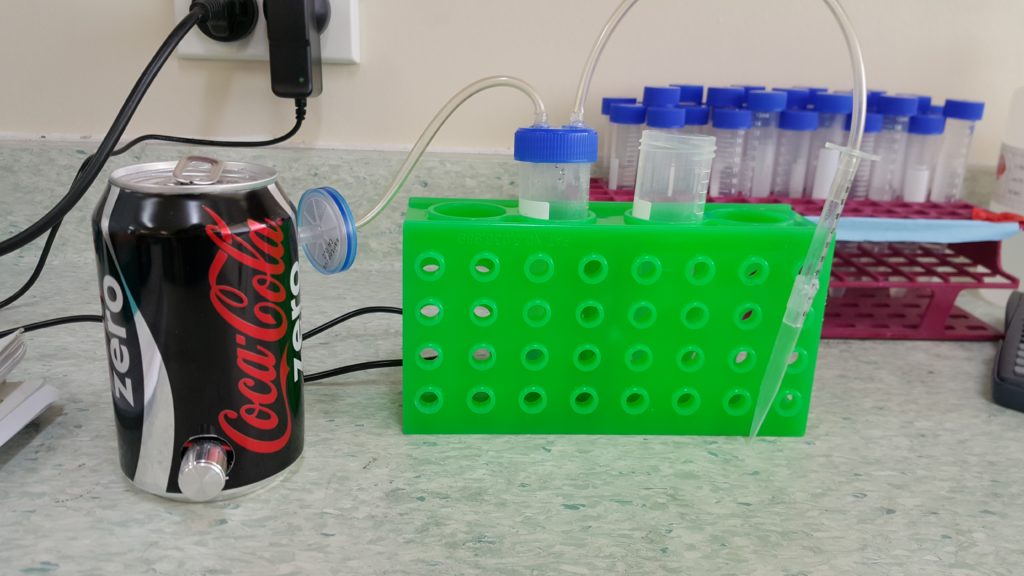

All jokes aside this monstrosity is off course not comparable to a proper commercial unit. But with some padding to reduce the noise and shaking, a bigger bottle and a proper box, a connector for the power so we could unplug the device easily, we managed to make it look and sound a whole lot better.

But a device like this with a more professional treatment and 10x markup should still only cost 200-400 USD… not 1800-3000… Someone with a 3D printer could make the exact same enclosure for a buck or two worth of resin or extrusion… and someone who is better than me in electronics could probably create a more efficient and cheaper controller board, or remove it all together and let the motor run at a fixed speed. Also keep in mind that this is done as a one off, if we would bulk order these parts, our costs also drop substantially.

The fact that laboratory equipment suppliers have made us believe we need their overpriced products is astounding, and is also resulting in gate keeping. Smaller labs in less funded countries cannot buy this expensive equipment, while big labs in richer countries get these types of machines often for free to test out, or get them at reduced rates because they order in bulk. Legislators are also made to believe it’s needed to buy more expensive equipment for safety reasons (which is true to a degree maybe, but they more often than not don’t come from the field and focus on the wrong hazards). A good tool, in the wrong hands is a bigger hazard than a bad tool in the right hands.